Why is the design of the stainless steel countersunk self tapping screws?

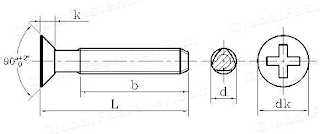

For those who purchase screws, the weight of the screws is also important to them because the weight of the screws is also related to their purchase cost. Mr. Xing’s stainless steel countersunk self tapping screws were designed to be fully threaded at the beginning. But because the length of this stainless steel countersunk self tapping screws is too long, there are 85mm, the cost of cavities will be very expensive, and later they are changed to half thread. And the drawn drawings were given to the Shi Shi Tong screw manufacturers. After reading the drawings of Mr. Xing, Shi Shi Tong screw manufacturer asked Mr. Xing whether there is any requirement for the diameter of the rod of the stainless steel countersunk self tapping screws . Mr. Xing’s screw thread diameter is 5mm. If the rod diameter is designed to be 4.6mm-5.0mm, then it is necessary to open the mold. If the rod diameter is designed to be 4.0mm-4.3mm, then no mold opening is r...